TANRU

TANRU

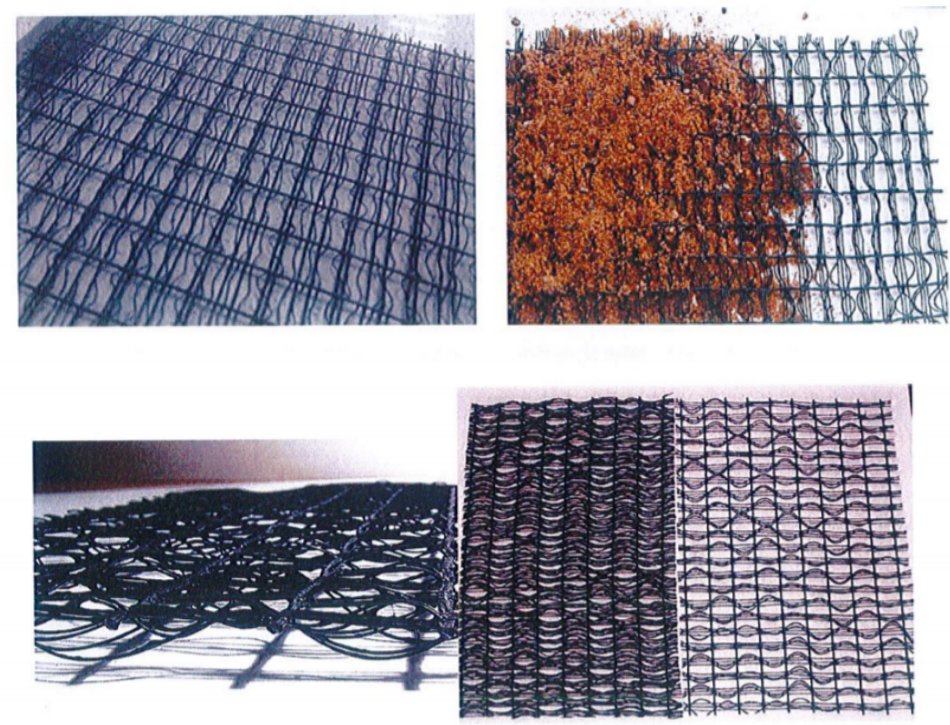

H-RECS is a three-dimensional structural net made of high-strength polyester fiber, covered with an anti-erosion and aging-resistant coating. It has two major functions: preventing erosion and promoting plant growth.

The principles of H-RECS spraying technology are mainly two aspects: first, before the turf is formed, the reinforcement and anchoring effect of the grass net can protect the slope from wind and rain erosion; second, after the turf grows, the plant roots are entangled with the three-dimensional mesh bars to form an overall modular structure with high tensile strength, which can increase the grass coverage area and increase the fiber density of the plant root system. The high tensile strength of the grass net itself can significantly increase the strength of the plant roots.

This material is made of polyester industrial filament yarn combined with a corrosion-resistant and aging-resistant coating. Leveraging the high strength and durability of industrial polyester filament yarn, the base fabric is processed using a biaxial warp knitting machine. A coating process is also employed to fully impregnate and encapsulate the polyester industrial filament yarn with the soft outer coating, enhancing the material's protective effectiveness and overall integrity. The material can be laid in widths up to 5.2 meters, ensuring efficient installation. Colors can be selected in black, green, or sandy yellow, depending on project requirements.

Construction process of 3D grass net spraying technology

(1) Clean the slope to the design requirements, remove weeds and trees, and spray pesticides to inhibit weed growth. Cover the slope with 20~30cm thick soil. The thickness of the soil depends on the soil type and the flatness of the slope.

(2) According to the dryness and wetness of the slope, water the slope to make it wet so that there is no loose soil or dust.

(3) Lay the grass net mat along the slope from top to bottom and level it. Fix the net mat with U-shaped nails. The U-shaped nails are staggered with a vertical spacing of 100cm and a horizontal spacing of 150cm. Steel nails are used to fix the net mat so that it is close to the slope.

(4) The grass net is fixed with a buried ditch or U-shaped nails at the top of the slope. The grass net at the foot of the slope is buried in the fill soil. The grass net is pressed under the cast-in-place slope platform at the two-level slope platform.

(5) When laying the second grass net, overlap it with the first grass net by 10-15cm. Use U-shaped nails to fix the overlap. The spacing of the U-shaped nails on the slope is 1m.

(6) The grass net should be rolled 5-10cm around the contact area between the grass net and the structure, and pressed with U-shaped nails to ensure that the grass net is in close contact with the surrounding structure.

(7) After the grass net is laid and fixed, fine-grained soil and fertilizer are spread manually from the top of the slope to the bottom to cover the net.

(8) Because the size of the grass net is small, in order to ensure the density of the backfill soil, it should be divided into three steps. Screening backfill soil: The sieve holes are smaller than the tree holes of the three-dimensional vegetation. After screening, the first backfill is carried out from top to bottom and compacted (do not use wet soil). Water spraying sedimentation: After the first backfill, use a high-pressure water truck to water it thoroughly and let the backfill soil settle naturally to prevent "hollowing" phenomenon. The second backfill method is the same as above. After the second backfill, the net, soil and slope soil have basically formed a whole, but there are a few "hollow" places. Use a mud pump to spray mud again to further increase the density and reduce the "hollow" phenomenon to a minimum or even no more.

(9) Use a hydraulic sprayer to evenly spray a mixture of seeds, fertilizers, soil improvers, water retaining agents and water on the slope. After spraying, sprinkle a little soil as needed to cover the net bag.

(10) The role of the meadow is to prevent water from eroding the slope and seeds, retain water and heat, and facilitate the germination and growth of flowers and grass seeds. After covering, use medium Φ4 "U" nails to fix it.

(11) Maintenance is divided into early, middle and late maintenance. In the early stages of maintenance, sprinkler irrigation is the primary method, keeping the soil moist to promote seed germination and rapid growth. In the mid-term, maintenance relies on natural rainwater. In case of drought, sprinkler irrigation should be applied 1-2 times per month. In the later stages, sprinkler irrigation should be applied twice per month, and topdressing fertilizer should be applied to promote seedling greening. Pests and diseases should be promptly detected and prevented.

To ensure that the vegetation produced by 3D grass net spraying technology enhances slope stabilization and achieves plant diversity similar to natural vegetation, ecological planting methods can be incorporated during construction. For example, an appropriate amount of native and wild shrub seeds can be mixed with the grass seeds during spraying. Alternatively, after the nets are hung, pits can be dug to plant trees and shrubs such as banyan trees and hairy lilac. Alternatively, after the grass cover is applied, pits can be used to plant native shrubs such as thorn, hollyhock, oleander, and wild peony. This creates a natural mountain forest effect, achieving ecological soil stabilization and slope protection, as well as greening and beautifying the environment. This greening and protection method has been tested and promoted in quarry slope improvement and greening projects, achieving very satisfactory results.